About

Resources

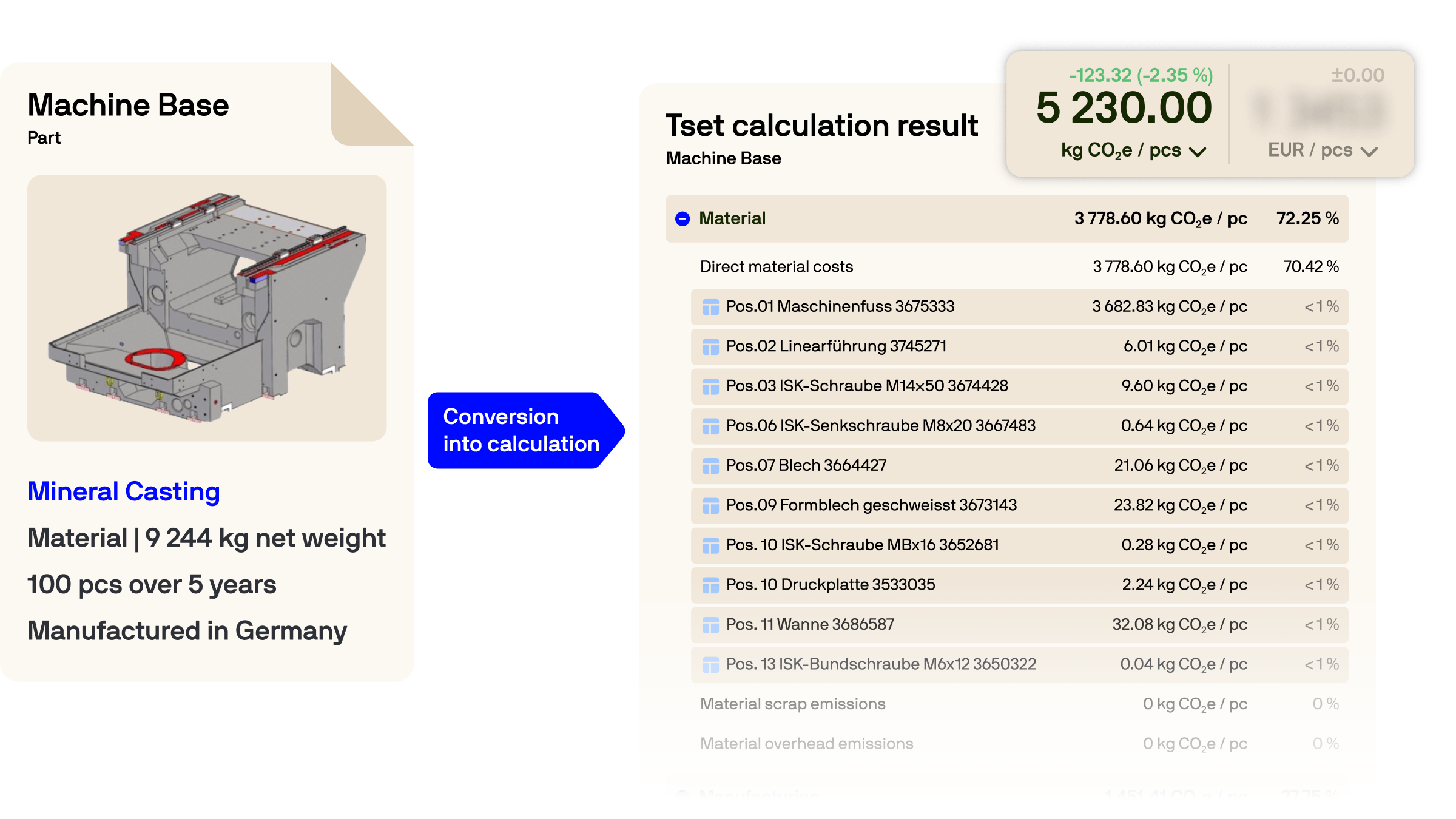

How does Chiron determine product costs and CO₂ emissions with Tset?

02.07.2024

Chiron, one of the global market leaders for milling and milling-turning centres, uses the Tset software for cost management in product development. The innovative solution empowers the customer to enhance cost efficiency and competitiveness.

About the customer

The CHIRON Group from Tuttlingen, Germany is one of the world's leading suppliers of machining centres and solutions. The machine manufacturer is present in all important markets such as the automotive industry and medical technology. "Performance meets precision" is the promise that the 1, 900-employee company extends to its customers.

Starting point

When thinking about cost management, one always has the high level of integration effort in mind. Chiron therefore was also reluctant to use conventional cost engineering software for a long time. In order to determine the expected costs and CO₂ emissions of new product developments, the company relied on empirical values from comparable, existing products - a common method in the industry. However, in many cases the outdated figures have nothing to do with the dynamic world of product development. Economic, ecological and political factors play a central role in this - and are usually subject to strong, sometimes abrupt changes. A solid and well-structured cost management system was needed to guarantee the profitability, sustainability and success of new product developments. A cost management system that promises flexibility, speed and precision.

"We were interested in a more efficient method of cost management. As the topic of sustainability has become increasingly important to us, we wanted to find a solution that would also help us to operate in an even more environmentally conscious way."

Dr Claus Eppler, CTO Chiron Group

Solution

Whether for product cost predictions, price negotiations with suppliers or production optimisation, the Tset software is now used in various instances at Chiron. This enables Chiron to recognise cost optimisation potential at an early stage and switch to more efficient production methods if necessary. Detailed post-production calculations allow actual costs to be compared with planned costs and insights to be derived for future projects. Above all, the software scores highly in terms of flexibility, as functions and cost-sensitive variables can be customised to the specific circumstances of the product in question.

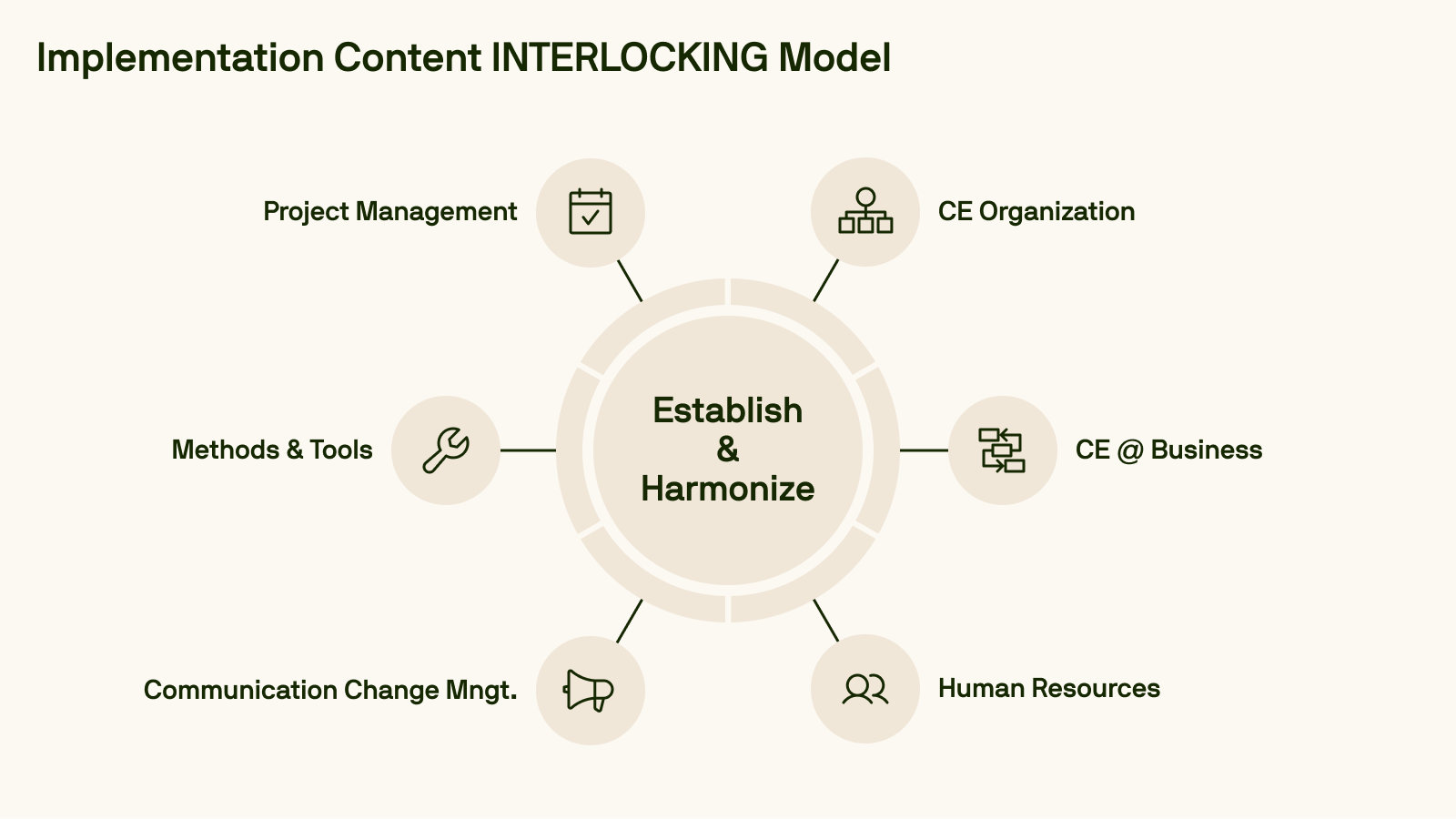

The search for a suitable software-as-a-service solution brought Tset into play as a reliable partner. In order to successfully implement our software, we provided Chiron with interim managers who helped the company set up its own cost engineering department and restructure its global procurement management.

"The Tset software creates a solid basis for successful decisions in product development. At the same time, we can keep an eye on our CO₂ emissions and identify environmentally friendly solutions with no additional effort. The fact that we can systematically and automatically calculate the carbon footprint of our machine, and even of individual machine components, makes the Tset software the ideal solution for our requirements."

Dr. Ing. Claus Eppler, CTO CHIRON Group

At a glance - the advantages of Tset for Chiron:

By supporting Chiron in setting up its own cost engineering department, we were able to contribute to long-term success in cost and CO₂ management.

1 .

Cost reductions in the individual project phases

2 .

More productive manufacturing processes

3 .

Faster decision-making

As a next step, Chiron plans to extend the use of the software to other areas of the company. We will of course also be providing our advice and support to the supplier of machining centres in this regard.