For manufacturers worldwide, balancing carbon emissions with the cost of production has become a critical focus. The rising costs of carbon emissions present a significant challenge, highlighting the urgent need for cost-conscious CO₂ reduction strategies in sustainable manufacturing.

The Rising Cost of Carbon: Global Pricing Trends

Governments worldwide are implementing diverse strategies for greenhouse gas pricing, including emissions trading systems, carbon taxes, and hybrid approaches. The coverage and pricing of these instruments vary significantly across jurisdictions, encompassing different emitters, gases, sectors, and locations. While no single jurisdiction currently achieves 100% coverage, some, like Sweden, combine multiple instruments to reach high coverage rates of 70-80%.

Looking ahead, carbon prices are projected to increase substantially over the next 5-10 years, potentially approaching the actual social cost of carbon. If this trend gains widespread support across jurisdictions, it will transform the manufacturing industry. Adapting to these rising price levies will become crucial for businesses to maintain competitiveness and sustainability in this evolving landscape.

Navigating the Regulatory Landscape

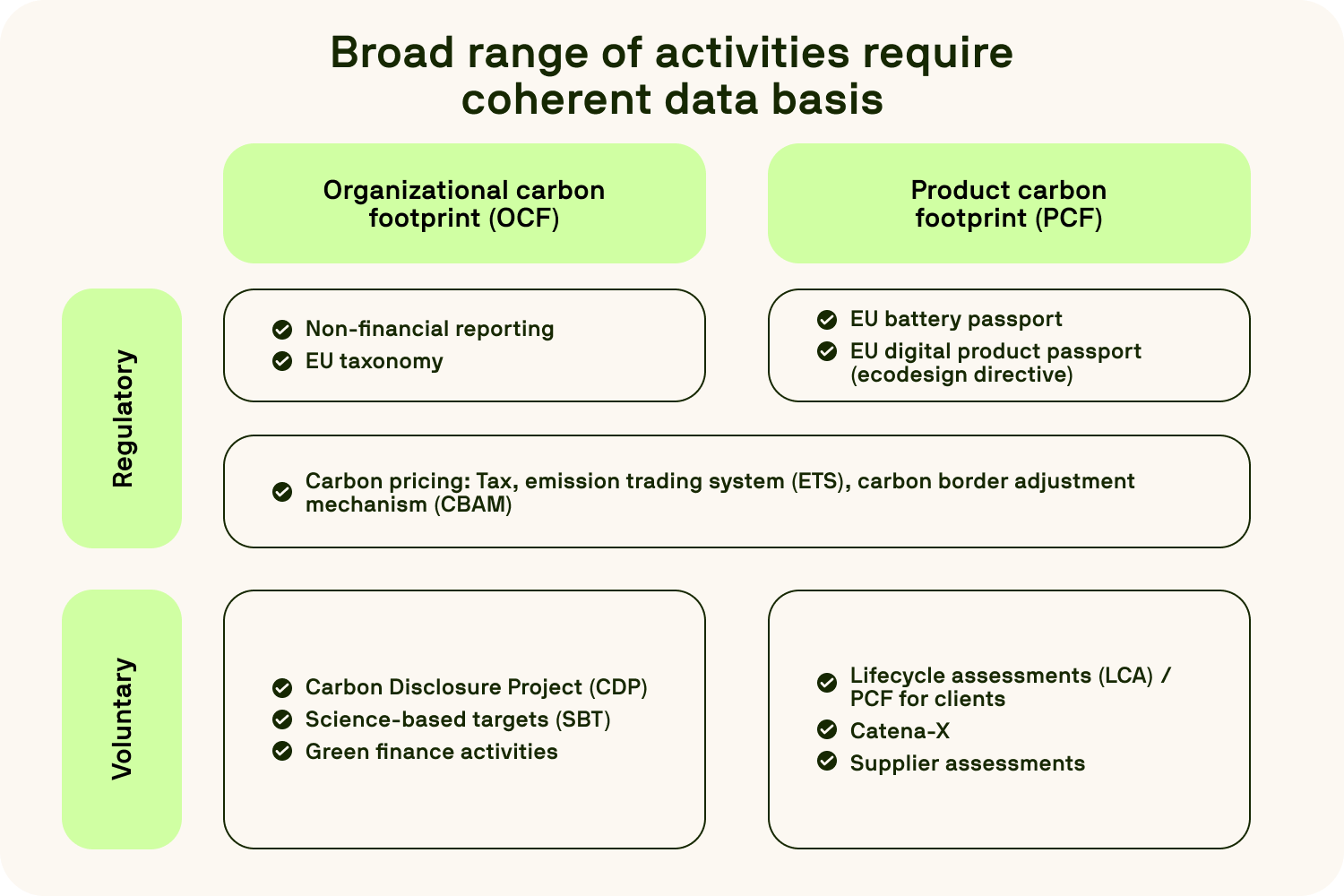

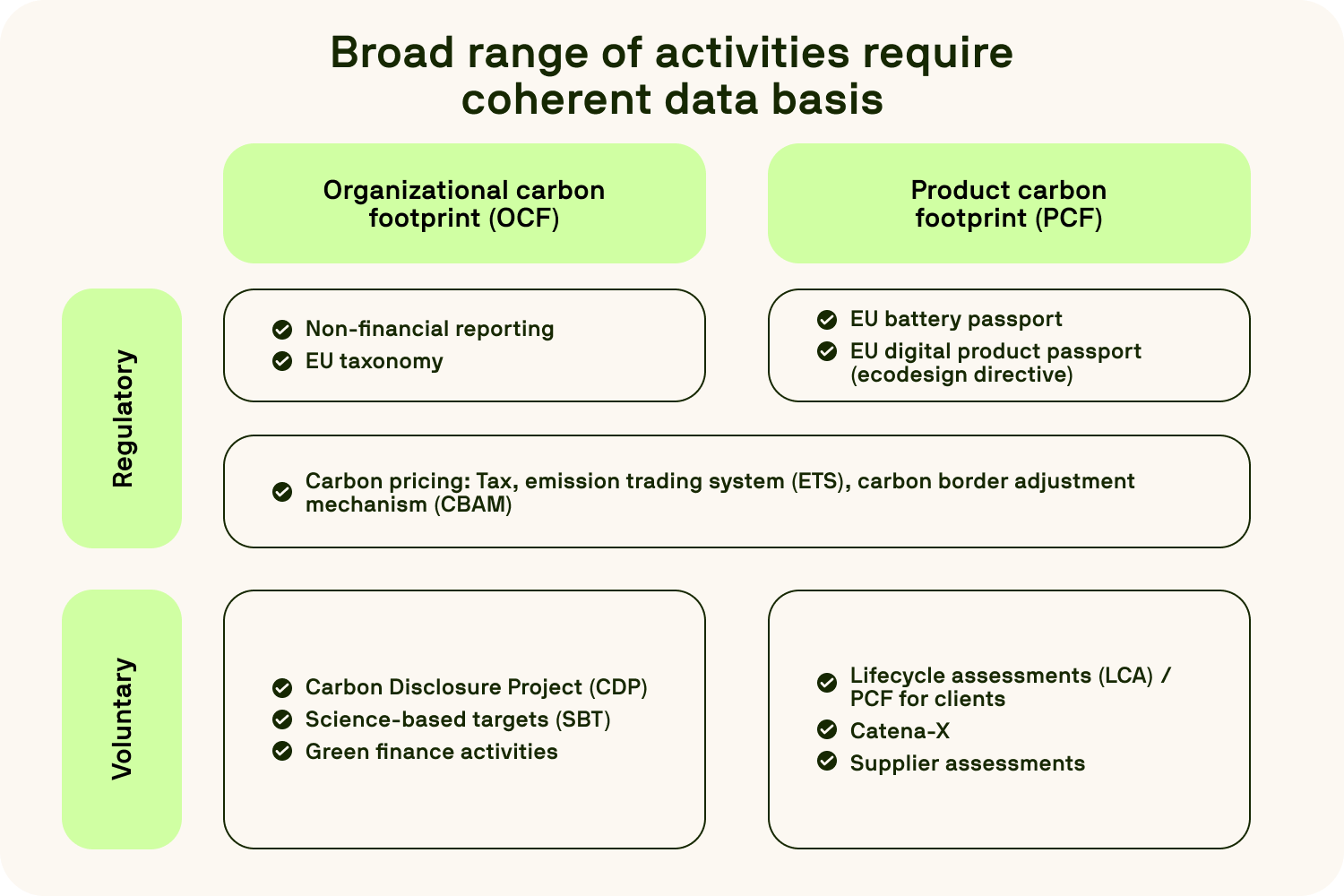

Beyond carbon pricing, which affects both organizational and product carbon footprints by increasing costs, there are various other instruments at play. These can be either voluntary or compulsory and may focus on either organizational or product carbon footprints. The implementation of such regulatory frameworks is particularly prevalent in Europe. For example, the European Union has introduced a taxonomy for green and brown business activities, providing a framework for sustainable economic practices. Additionally, the Carbon Disclosure Project offers a platform for organizations to report their carbon footprint. On the horizon, the European Union is developing a Digital Product Passport, which will require companies to disclose the environmental impact of their products throughout their lifecycle.